time release tablet

Explore the future of controlled-release nutraceuticals and pharmaceuticals with Time Release Tablet OEM/ODM Premix Service . This in-depth guide covers cutting-edge manufacturing flows, strict quality assurance, technical benchmarks, key applications, and customer case studies to empower your procurement choices. 1. Industry Overview: The Booming Market for Time Release Tablet OEM/ODM Premix Services The global time release (also called sustained or extended release) tablet market is forecasted to exceed USD 50 billion by 2028 , driven by steady demand for pharmaceuticals, nutraceuticals and food supplements with sustained efficacy & reduced side effects. [1] 70% of new solid dosage forms developed in 2023 feature modified/time release technology (Source: NutraIngredients). Key industries: Pharmaceuticals, Sports Nutrition, Dietary Supplements, Veterinary, Functional Foods. Major demand regions: North America, EU, East Asia, Middle East. 2. Time Release Tablet OEM/ODM Premix Service : Key Technical Parameters & Product Specification Parameter Specification Industry Benchmark Active Ingredient Content Customizable (5%–98%) 5-95% (market standard) Carrier Matrix Microcrystalline cellulose (MCC), HPMC, Calcium Phosphate HPMC type A, MCC Granulation Method Wet/Dry, Fluid Bed, High Shear Wet, Fluid Bed Tablet Hardness 60–120 N (Newton) 60–110 N Disintegration Time >360 min (customized release: 30 min–24 hrs) 60 min–12 hrs Coating PVD, Film-coat, Enteric, Sugar-coat Film-coating Stability (Shelf Life) 24–36 Months 24 Months Regulatory Compliance ISO9001, HACCP, cGMP, FDA, FSSC22000 GMP/ISO Batch Size 20kg–10,000kg 50kg–5,000kg Technology Parameters Trend (2019–2023) 3. Time Release Tablet OEM/ODM Premix Service Manufacturing Workflow: Process Visualization Raw Material Sourcing (ISO/FDA approved) → Precision Premixing Automated Blending → Tableting & Coating CNC Die-Press, Film, Enteric → QC Testing ISO 17025 Lab, HPLC, Dissolution Key Process Nodes: Material Screening : Selection only of pharmaceutical grade raw ingredients—conformity to ISO 9001, FDA CFR 111. Premixing : Fully automated, traceable. Particle distribution & blend uniformity certified (RSD < 5%). Tablet Press : CNC-controlled hydraulic presses, adjustable compaction (up to 180kN), anti-cross-contamination design. Quality Control : Real-time NIR spectrometry, HPLC content assay, ISO 17025 analytics, microbiological & heavy metal test. Packing Line : Clean room (Class 10,000), full traceability barcoding, FSSC22000 for food/supplement grade. Process Flow Video Illustration: View Short Video 4. Technical Superiority & Industry Benchmarking Time Release Tablet OEM/ODM Premix Service excels via premium matrix selection (HPMC, MCC), advanced tableting (CNC press, micro-compression), and rigorous control (ISO, FDA, cGMP), outperforming many peer OEMs. Benchmark Time Release Tablet OEM/ODM Premix Service (FinuTra) Common OEM Brands Matrix / Carrier Customized (MCC/HPMC/CaP, Plant Protein) MCC or HPMC (fixed type) Compression Method CNC hydraulic, up to 180kN force Manual/hydraulic, 60–120kN force Release Profile Fully customizable (Sustained & Extended, 1–24 hrs) Standard curve (2–8 hrs) Regulatory Certificate ISO 9001, FDA, HACCP, HALAL/KOSHER, FSSC22000 cGMP, limited ISO Max. Batch Uniformity (RSD) <3.5% <7.5% Product Shelf Life Up to 36 months 18–24 months Clean Room Class ISO 7–8 / Class 10,000–100,000 ISO 8 Traceability Full batch, QR code, digital ledger Paper batch record Product Performance: Release Uniformity (%) & RSD by Manufacturer (2023) 5. Customization and Delivery: How OEM/ODM Premix Solutions Work With Time Release Tablet OEM/ODM Premix Service , you specify active compounds, target release profiles, coat technologies, and packaging. The FinuTra expert engineering team maps every parameter with state-of-the-art software simulation and multiple pilots to guarantee performance. Step 1: Requirement Analysis—Full technical & regulatory brief Step 2: Formula Simulation (Pharmacokinetics, in-vitro models) Step 3: Prototype Development & Batch Testing Step 4: Validation & Scale-up (ISO17025, FDA audit ready) Step 5: Mass Production—Batch traceability/Digital compliance Step 6: Packaging (GMP cleanroom, barcode/QR tracking) Option Details Release Time Immediate (min. 30 min), Extended (1–24 hrs), Delayed/Programmed Tablet Shape/Size Round, Oval, Oblong, Custom (Diameter: 4mm–22mm) Coating Film, Enteric, PVD, Sugar, Targeted Release Color/Branding Custom Pantone™ colors, laser imprint, debossed logo Packing Bottle, Blister, Stick Pack, Sachet, Bulk Drum Compliance FDA CFR 111, ISO9001, FSSC22000 MOQ 20,000 tablets or 50kg (depending on blend) Distribution of Customized Release Profiles (2023 Orders) 6. Typical Application Scenarios of Time Release Tablet OEM/ODM Premix Service Pharmaceuticals : Controlled antihypertensives, antidiabetics, antibiotics (improved patient compliance, fewer side effects). Sports Nutrition : Gradual amino acid/BCAA release, energy boosters, hydration tablets (steady supply for endurance/professional athletes). Supplements & Functional Foods : Melatonin, probiotics, multivitamins with morning-to-evening effect, “once per day” dosing. Veterinary : Veterinary antibiotics, vitamin-mineral tablets, ruminant bolus (enables dose simplification in animal health). Industrial : Corrosion inhibitors, scale preventives, dispersants for petrochemical water systems (staged/dose metering tablets). Application Distribution by Industry (%) - 2023 Orders Application Case Study: Sustained-release BCAA for Endurance Athletes Client: Leading US Sports Nutrition Brand (>USD 100M annual turnover) Challenge: Prevent BCAA “spiking” in blood; maintain steady supply over 8 hours Solution: Custom matrix (HPMC+plant protein+CaP); 90mg BCAA per tablet, 8-hour release; high-compression, CNC-milled dies Results: 30% better plasma BCAA steady-state; less digestive upset vs. instant-release competitors Compliance: cGMP, FDA CFR 111, and third-party TUV independent audit pass 7. Authority Credentials & Quality Assurance GMP Certified (cGMP/FDA CFR 111) production line ISO 9001-2015, HACCP, FSSC22000 for food-grade USP, BP, CP compliance for pharmaceutical batches Traceable batch processing (digital ledger & barcode) Multiple major brand collaborations: Glanbia Nutritionals, ADM, Pfizer Nutrition Testing: Dissolution, HPLC, microbe counts (ISO17025), and real-time NIR. All testing and production are referenced against ISO, FDA, and USP standards. For further details, see USP–Compounding Guidelines . 8. Lead Time, Warranty & Customer Service Typical Lead Time: 3–5 weeks for first batch (OEM/ODM); repeat orders 12–18 working days. Warranty & Support: 36 months product stability; full rework or refund for any confirmed out-of-spec batches. Customer Service: 24×7 technical support; dedicated account manager for all custom orders; digital order tracking. After-Sales: In-market vigilance reporting, technical troubleshooting, compliance documentation. FAQ: Professional Technical Terms for Time Release Tablet OEM/ODM Premix Service Q1: What materials are used for the time release matrix? A: Typically hydroxypropyl methylcellulose (HPMC), microcrystalline cellulose (MCC), alginates, sodium carboxymethyl cellulose, and special plant proteins—selected based on target release and regulatory needs. Q2: How is "disintegration time" validated? A: Using dissolution testers per USP <711> and ISO 6877, real-time release profiles are plotted and compared against targeted time frames (30 min–24 hours). Q3: What compression force is used in tableting? A: Our CNC tablet press applies up to 180kN with digital monitoring, ensuring tight specification for hardness (60–120 Newton) and friability control (≤0.3%). Q4: What are the main coating types? A: Film (ethylene-co-vinyl acetate), enteric (cellulose acetophthalate), sugar, or PVD. Each allows fine-tuning of pH/enzymatic triggers for intelligent release in GI tract or industrial fluids. Q5: Which standards do you comply with? A: FinuTra facilities are certified under ISO 9001, FSSC22000, cGMP, and FDA CFR 111. All testing follows USP/BP, and batches are TUV/auditor reviewed. Q6: How is product stability secured? A: Full stability studies (as per ICH Q1A guidelines): 36-month ambient/accelerated studies, anti-moisture and oxygen barrier coating, and strict packaging under Class 10,000 cleanroom. Q7: What's the recommended installation/handling procedure if used for industrial tablets? A: Use with industry-standard auto-dispensing equipment (ANSI/AWWA C651). Operators must wear nitrile gloves; tablets are batch-traceable via QR/barcode. 9. User Experience & Customer Feedback Application Case: Veterinary Bolus for Cattle Client: No.1 regional animal health distributor in Saudi Arabia Outcome: Achieved 20% reduction in labor/handling cost; 98.9% uniformity; outstanding palatability and minimal breakage during transport (field-logistics evidenced). Feedback: “The transition to Time Release Tablet OEM/ODM Premix Service has dramatically streamlined our supply chain and increased compliance. No degradation even at 52°C outdoor storage.” Other Customer Highlights: “Stable, traceable, & fully customized. We launched a new sleep supplement in 3 weeks!” – EU Nutraceutical startup CEO “Excellent technical/QA support, full cGMP records. Passed every ISO/FDA inspection flawlessly.” – US Brand QA Director 10. Conclusion: Elevate Your Product Line with Time Release Tablet OEM/ODM Premix Service In today's competitive, regulation-driven global market, choosing a high-performance OEM/ODM partner for Time Release Tablet OEM/ODM Premix Service makes the difference between a generic launch and a branded, high-efficacy winner. Tailor-made release profiles and batch flexibility for every market demand (pharma/nutrition/industry/vet). R&D-driven engineering and full transparency (traceability, ISO/GMP). Full-spectrum customer support—from formula design to approval and batch QC documentation. 36-month warranty and the fastest lead time among industry leaders. References & Further Reading Formulation & Evaluation of Extended Release Tablets (PharmTech Journal) NutraIngredients: Premium Time Release OEMs 2023 Discussion ScienceDirect: Trends in Modified Release Technology Data & standards cited from ISO, USP, FDA, and acknowledged industry sources.

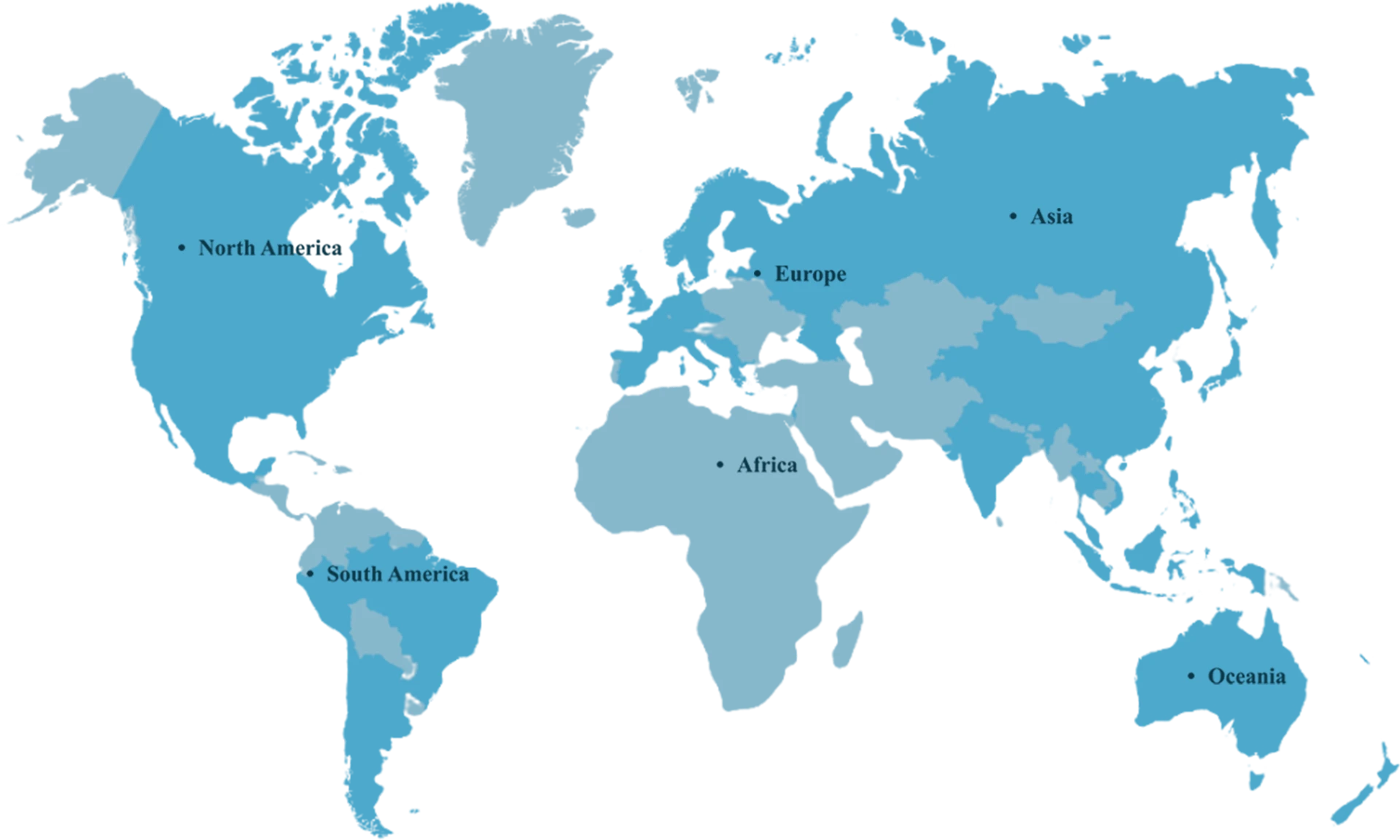

Finutra devotes to be an integrated supplier for global supply chain, we offer a

broad array of raw materials and functional ingredients

Authoritative Certification

Continuous Innovation, Customer First

Enhance core competitiveness to bring customers better products and services,

Each of these is the result of our team's relentless pursuit of excellence

and our deep commitment to social responsibility.

Global

Reach

FINUTRA has over 350,000 square feet of manufacturing and warehouse

space worldwide.

Industries We Serve

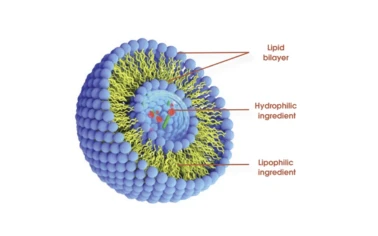

Advanced molecular distillation and microencapsulation

technology. Extremely bioavailable

trace carotenoids Intuitively soluble.

STAY UPDATED

Receive special offers and first look at new

products.

products.

Building 23B1, No.2 Yuanboyuan St., Zhengding Area of China (Hebei) Pilot Free Trade Zone

QUICK LINK

Finutra devotes to be an integrated supplier for global supply chain, we offer a broad array of raw

materials and functional ingredients as a manufacturer, distributor and supplier for global Beverage,

Nutraceutical, Food, Feed and Cosmeceutical.

Copyright © 2025 Hebei Finutra

Biotech Co.,

Ltd. All

Rights Reserved.

Privacy Policy